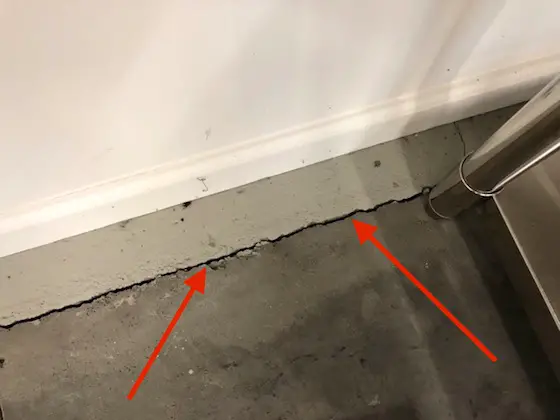

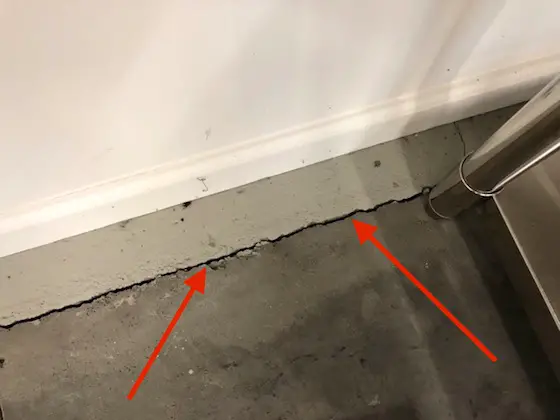

Concrete Cracks

Concrete shrinkage cracks look just like this. The darker gray concrete slab touched the lighter gray foundation the day it was poured. Over a period of months, even up to a year or more, the concrete slab shrinks in size and creates a gap. Copyright 2018 Tim Carter

"On average, a concrete slab shrinks 1/16th inch for every ten linear feet."

Concrete Shrinkage Cracks Checklist

- Concrete shrinks over time as it hardens and subsequently cures

- Shrinkage creates tension forces that can rip the concrete apart

- Control joints in the concrete help to prevent ugly random cracking

- Shrinkage is about 1/16th inch for every ten linear feet

Related Links

Magic Concrete Crack Epoxy - Fixes Concrete Cracks

Reinforcing Steel in Concrete - Best Way to Hold Concrete Together

Concrete Shrinkage Cracks Cause Anguish and Arguments

Concrete gets smaller as the water in the concrete ever so slowly evaporates from the artificial stone.

I receive calls and emails from homeowners all the time about cracks that appear in new concrete sidewalks, driveways, patios, basement floors, slabs on grade, and foundation walls. Most homeowners are quite upset by the cracks.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local concrete contractors.

Do Contractors Know Concrete Shrinks?

I don't think that most contractors know the true cause of cracks in concrete. They'll tell you that cracks are normal and shrug their shoulders.

Years ago, when I was still building, I discovered that concrete shrinks as it dries and cures. On average, a concrete slab shrinks 1/16th inch for every ten linear feet. This may not seem much to you, but what this shrinkage does is produce significant internal stress within the slab.

What Happens When Concrete Shrinks?

As concrete shrinks, stress is created within the slab. This stress or force is considered a tension-type force as the concrete is trying to pull itself apart much as you pull on two ends of a piece of newspaper. Pull hard enough and the paper tears.

Because I knew there was a chance for concrete to crack, I actually had a special section of my contract that told people I guaranteed their concrete would crack.

I realize this sounds nuts, but that sentence in the contract afforded me with enormous protection. I further stated in my contract that I would do everything in my power to minimize the cracks and encourage the concrete to crack at predetermined locations. But even with all of this, the concrete could develop a random crack all on its own.

Can You Control Where Concrete Cracks?

You can encourage concrete to crack where you want, but I wouldn't always guarantee this. The best way is to create a crease or straight line in the fresh concrete. Large slabs, driveways, sidewalks, etc. will require many of these lines. Contractors call them control joints because you try to control where the concrete will crack.

Surely, you have had to tear a piece of paper in half before and not had a scissors handy. If so, you probably creased the paper with your fingernail several times and then tore the paper neatly along this crease. The creasing action creates a pre-weakened zone in the paper by bending and breaking some of the fibers in the sheet of paper.

CLICK HERE to get FREE & FAST BIDS from local concrete contractors.

How are Concrete Control Joints Created?

Concrete masons create control joints by creating a line in concrete slabs as they are finished or immediately after they are poured. A saw cut or tooled line that creates a groove in a slab actually reduces the thickness of the slab at that location and makes it easier for the slab to crack. In the trade, these lines are called control joints as we are trying to control where the crack will occur.

How Deep Should Control Joints Be?

The Portland Cement Association and the American Concrete Institute agree that the minimum depth of a control joint should be 1/4th the thickness of a slab. This means the grooved lines you see in a typical sidewalk should be one inch deep, as many sidewalks are poured four inches thick.

Measure your grooves and guess what? I'll wager they are only 5/8 inch deep or perhaps 3/4 inch if you're lucky. A concrete saw can be placed in these grooves to increase the depth of the groove.

Will Steel or Mesh Help Hold Concrete Together?

Placing reinforcing steel, wire mesh, and even synthetic fiberglass fibers in with the concrete will help hold the concrete together in the event it does crack. I'm a huge fan of one-half inch steel bars placed at two-foot-on-center intervals in slabs poured on grade.

Reinforcing steel is the best thing you can include when pouring concrete. When concrete cracks, the steel holds it together. (C) Copyright 2018 Tim Carter

This steel works well if it is in the center of the slab or just slightly below the center point. The steel has a far greater tensile strength than the concrete and holds the artificial rock together much the same way as the strings you find in common brown packaging tape.

How Do You Hold the Steel Bars Up During the Pour?

For years I've placed small pieces of solid brick under rebar to hold them up so they are suspended in the air and concrete can flow under and around the steel bars. If you're pouring a 4-inch-thick slab, you want about 1.5 inches of concrete under the bars. If the brick is thicker than 1.5 inches, then you need to dig a small recess for the brick to rest in so it puts the steel at the correct height.

Be sure you discuss what measures your builder intends to take to ensure your concrete cracks where it is supposed to crack. Keep in mind that your builder can't give you an absolute guarantee that the concrete will do what he or she says. If this person makes this lofty promise, then you might want to consider talking with another builder.

CLICK HERE to get FREE & FAST BIDS from local concrete contractors.

BXXX

Column NH055

42 Responses to Concrete Cracks