Check for Crowns in Lumber

The crown of a piece of dimensional rough lumber is the upward arching curvature you see when you look down its narrowest dimensional edge.

If you visit your new home construction site, and overhear parts of a conversation among the carpenters, you just might hear them discuss crowns. Your first inclination might be that one or more of them are members of a royal family. If that mental image doesn't connect, you might think one of the crew has some expensive dental work in their immediate future. But my guess is they were talking about the lumber with which they are working.

Traditional lumber floor joists and wall studs are rarely perfectly straight. Most of us wish they were straight so that walls and floors would be in the same plane. This would make the installation of both floor and wall cabinets a breeze. In fact, just about every finish material applied to a wall, floor or ceiling benefits when the framing members are in the same plane.

What is the crown of a piece of lumber?

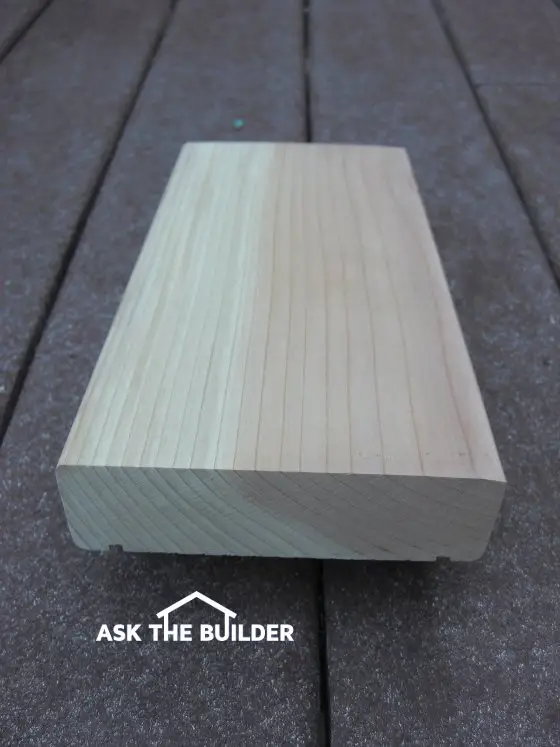

The crown of a piece of dimensional rough lumber is the upward arching curvature you see when you look down its narrowest dimensional edge. To see the crown of a common 2 by wall stud or floor joist, you drop one end of the board on the ground and pick up the other end. Rotate the piece of lumber so that the 1.5 inch wide surface is pointing to the sky. As you orient your eye, so that you are looking down this finished edge towards the ground, you will almost always see some amount of curvature. It is possible to have a piece of lumber that is perfectly straight or one with very little curvature, but they are few and far between.

How do you install lumber with a crown?

As carpenters build a floor or a wall, it is important that they pay attention to crowns. You want the curvature or crowns of all pieces of lumber in a wall or a floor to point the same direction. In the case of floors, you absolutely want the crowns of the joists to point to the sky after the joists are nailed in place. When walls are framed on the ground or a subfloor, carpenters often do the same thing. When the wall is tilted into position, the wall may have a very slight hump in it as the crowns face out instead of inward.

What is the maximum acceptable crown?

Some lumber may have excessive crowns. In my opinion, a 16 foot long floor joist should have no more than a one-half inch crown. You measure the amount of crown by snapping a chalk line from the two ends of the floor joist along the wide flat face of the lumber. The chalk line, when stretched tightly, represents a perfectly straight line between the two top ends of the joist. The lumber that exists above the chalk line is the crowned aspect of the lumber. Use a tape measure to determine the extent of the crown.

Crowns can create an issue if a severely crowned floor joist is installed next to one that has no or very little crown. As you walk across a floor, that has been framed in this manner, you often can feel the actual hump in the floor. Professional carpenters will always check each joist or wall stud for the amount of crown and mark them. The lumber that has severe crowns can be cut into shorter lengths and used for blocking or short structural header beams above doors and windows.

What are alternatives to lumber that is crowned?

There are other products your builder can use to eliminate crown problems. Engineered floor trusses and engineered I joists can be used. The floor trusses are made in a similar fashion to roof trusses. These are often made at the factory with a crown built into the floor truss, but once the floor is covered and furniture put into the room, the trusses are meant to flatten out to a large degree. The good news is that each separate floor truss has the exact amount of crown built into it so humps are a thing of the past. Wood I-joists are made with no built-in crown. Floors built with them are as flat as a tabletop.

If you want perfectly straight walls, your builder can order engineered lumber wall studs or use steel studs in critical locations. Straight walls are a must in bathrooms where tile will be installed and any wall that will accept cabinets and countertops. The framing carpenters can easily incorporate wood blocking between the steel studs. Many specifications require that a screw penetrate 1.5 inches into solid lumber in order to deliver a sufficient amount of holding power. The wood blocking meets this specification.

Column NH037

3 Responses to Check for Crowns in Lumber