Galvanized Nails – AVOID Cheap Ones

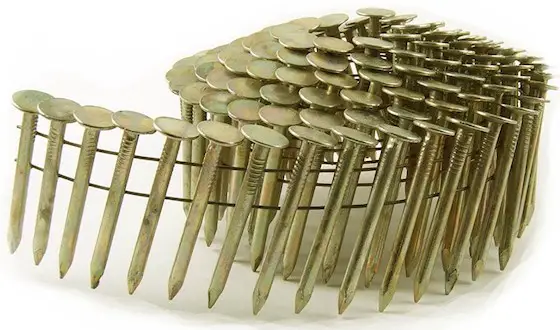

Galvanized Nails | All the nails have been galvanized. The one being held was electro-plated and it’s rusting after just 12 years. Next to it is a new electro-plated nail. The four gray ones are hot-dipped nails, some have a distinctive irregular coating of pure zinc. The irregular ingots are solid zinc. Photo Credit: Tim Carter

Galvanized Nails - Always Get Hot-Dipped Nails

- Hot dipped galvanized are the best nails

- Electroplated nails are the worst

- WATCH galvanizing process videos below

- Pay attention to labels on nail boxes

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I'm getting bids on a new roof and some of the roofers want to use a nail gun to install the shingles. Is this a good idea?

I've also heard stories about inferior galvanized nails that don't hold up and start to rust soon after being installed.

What type of nails would you use when installing shingles on your home and why? How can you tell the difference between different galvanized nails? Cheri B., McAlester, OK

DEAR CHERI: Roofing nail guns are mainstream now and accepted by just about every roofing material manufacturer that I know of.

Drive Nails Correctly

It's important the guns drive the nails correctly per the written instructions of the shingle manufacturer, so be sure to take the time to read the written installation instructions about this.

Nails Need To Outlast Roof Material

While you're checking out the instructions, pay attention to the type of nail the shingle manufacturer recommends so you don't void the warranty. Realize the fastener is the lifeline of the roofing material.

It's vital the fasteners last longer than the actual roofing material. If the nails or fasteners rust and fail, the shingles can succumb to gravity and/or be blown away in a moderate breeze.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local roofers who can supply the BEST NAILS.

Many Inferior Nails Used

You should be very concerned about using inferior roofing nails. I'm in the process right now of re-roofing my own home.

I didn't build the home I live in. It was constructed just fourteen years ago.

It had a heavy-duty architectural shingle on it that was supposed to last forty years, but it started to fail two years ago. You can read the saga of my failed asphalt shingle roof - Roofing Ripoff.

Cheap Nails

Now that I'm taking off the curled, brittle shingles that are losing granules by the minute, I see the roofer used cheaper electroplated galvanized nails, many of which are rusting.

Gold Standard

When it comes to galvanized nails for roofing, the gold standard is hot-dipped galvanized nails. These steel nails are cleaned chemically and then immersed in a vat of molten zinc that sometimes contains some lead.

The molten zinc is very hot, usually between 815 - 850 F.

Hot-Dipped Galvanizing Video

Watch this video to see the steps it takes to hot-dip galvanize any steel item. It's fascinating.

Fast Process

It doesn't take long for the steel nails to rise up to that temperature and when they do, the steel atoms vibrate rapidly and interlock with the zinc atoms creating a zinc-steel alloy that resists rust quite well.

When the nails come out of the molten zinc, they also have an additional coating of pure zinc on them.

CLICK HERE to get FREE & FAST BIDS from local roofers who can supply the BEST NAILS.

Best Dipped Twice

Zinc doesn't rust and the coating protects the steel from the ravages of water. The best nails get a second dipping in the molten zinc bath.

Other Ways Not So Good

There are three other processes of galvanizing nails, but they simply don't offer the level of protection as hot dipping. Hot galvanizing is a process whereby zinc dust or chips tumble in a hot drum with cold steel nails.

IMPORTANT TIP: The hot galvanizing process doesn't sufficiently heat up the steel to produce a zinc alloy on all the nails. This process is cheaper to do for nail manufacturers than hot dipping.

Mechanically Plated

Nails can also be mechanically plated with zinc dust. The cold steel nails tumble around with the zinc dust, tiny glass beads and a chemical.

The glass beads and the chemical work to apply a thin coating on zinc on the nails. Once again, this process doesn't create the all-important alloy and the zinc coating can be uneven and thin.

Electroplating - The Worst In My Opinion

The final process is electroplating. Here the cold steel nails are immersed in a chemical liquid where electricity is applied to the solution and a very thin coating of zinc is applied to the steel.

These are very common nails your roofer may use for your shingles. These are the WORST ones. They look gorgeous, but they're electroplated. DO NOT ACCEPT THESE. CLICK THE PHOTO to discover MORE about these nails.

This process produces very shiny nails that almost look like too good to be true. They don't have much zinc on them and as I can attest, they rust in short order when exposed to the elements. They can even rust when NOT EXPOSED.

In my case and in many roofs across the USA, electroplated nails are rusting just from the CONDENSATION under the shingles! This condensation happens on many nights when dew forms on the cool nails because water vapor is present under the shingles.

When the sun comes out and heats up the roof, the water evaporates. The process starts all over again when the sun goes down and the roof starts to cool.

Electroplating Galvanizing Video

Here's a poor quality video showing the electroplating process. Only the first 30 seconds and last 30 seconds are important to watch.

All the video in between is just the drum turning and the chemical coating the bare steel washers.

The white plastic tank contains a liquid chemical that's transferring the zinc to the bare washers. It's NOT a giant vat of PURE MOLTEN zinc.

New Hot-Dipped Nails

Years ago, it was impossible to locate hot-dipped galvanized nails that would be comparable with nail guns. Fortunately, it's possible to get them for just about any roofing nailer.

IMPORTANT TIP: Be sure your contract with the roofer specifies hot-dipped galvanized nails and pay close attention to the minimum length called for by the shingle manufacturer. Be sure you LOOK AT THE BOX LABELS when the roofers come. You want to see the words 'hot dipped' on the label.

Nail Length

If you're applying a thin shingle to a wood surface and no other shingles are present, you might be able to get by with nails that are only one and one-quarter-inch long. The shingle warranties are very specific about the nail length and you want the right nail so they have enough holding power to resist blowing off by strong winds.

Look At Label

To tell the difference between nails, you probably need a little bit of experience. The first thing to look at is the labeling on the boxes or containers the nails come in.

The wording must say hot-dipped. If you just see the word *galvanized*, that's not enough. Don't be fooled by the words *hot galvanized* either. CLICK HERE to see a label with false advertising on it. These were being sold at one of the big box retailers you probably go to all the time!!!!1

It's got to say hot-dipped galvanized.

Traditional Hot-Dipped Nails

Hot-dipped galvanized nails not used in a nail gun are usually very distinctive. Often they have clumps of zinc on the shaft or the coating of zinc is somewhat uneven on some of the nails. Go back up and look at the photo of these nails at the top of this column.

You may even discover small ingots of zinc in the box or nail container. Other methods of galvanizing leave a much smoother appearance on the nail surfaces than hot dipping.

The Nails I Use

I'm using hot-dipped nails because I want no rusting. I want my realistic and gorgeous synthetic slate shingles to stay attached to my roof when any number of punishing nor'easter storms pummel my house with howling gale-force winds.

I have a feeling I'll be out the next day helping to secure my neighbors' roofs because their roofers chose to use the cheaper nails. Don't you make that mistake.

CLICK HERE to get FREE & FAST BIDS from local roofers who can supply the BEST NAILS.

Column 1097

9 Responses to Galvanized Nails – AVOID Cheap Ones