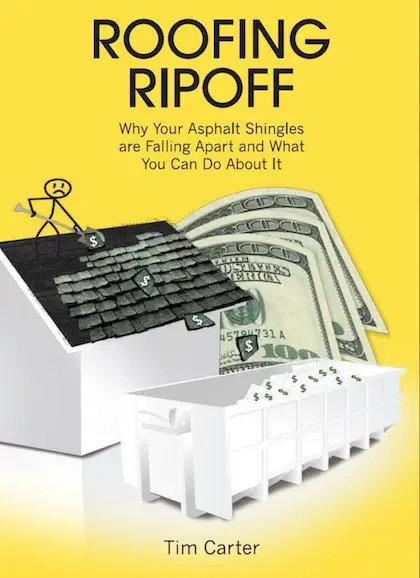

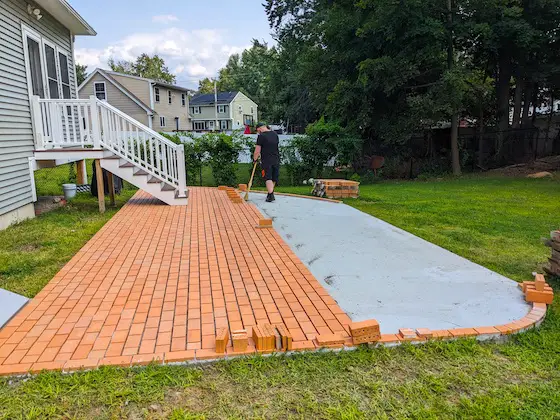

Clay Paving Brick | You’re looking at spilt clay paving brick I’m installing at my son’s house. These bricks will never change color and can last hundreds of years. They are not inferior like brick pavers made from concrete. Look at the photos here of how concrete pavers change color and erode. Copyright 2023 Tim Carter

Clay Paving Brick are the Best - Forget About Concrete Pavers

If you read my column on a regular basis, then you know about two months ago I touched on the perils of using paving brick made from concrete. That column talked about how those bricks fade in color over time as the thin colored cement paste succumbs to Mother Nature and high-pressure streams of water that rush out of the ends of pressure-washing wands.

I shared at the end of that column a project I’m working on at my son’s new home. Each weekend he and I are bonding while sweating profusely as we install perhaps the best pavers known to man. They’re made from clay and so durable they can be used to construct roadways. The color will never fade, and if one of the bricks gets chipped the color and texture inside the brick are the same as what you see on top. We’re using pavers made from clay and fired in a kiln until they’re as hard as rock.

I’ve used clay paving bricks on the past two homes I occupied in Cincinnati, Ohio. My son learned to walk on the last clay paver patio I built in the rear yard of the stunning Queen Anne Victorian home I built there. Twenty years before that I had installed a similar clay paver patio at the second house my wife and I owned. That patio looks as good today as the day I installed it back in the late 1970s.

It's taken a total of about 40 man hours, me laying the brick and my son mixing mortar, to get this far. All the bricks will be installed in just two more days of work. Then it's time to fill the gaps with high-strength grout. Copyright 2023 Tim Carter

I was introduced to clay paving brick by my future mother-in-law. When I was dating my wife, I noticed one evening two pallets of used salvage pavers sitting in the driveway. I asked about them and soon discovered they were destined to form a wonderful patio in the rear of her house under two magnificent shade trees.

One thing led to another and I volunteered to install the brick under the guidance of my future father-in-law who was far too busy with his medical occupation. Among other things, he taught me how to create a baseline to ensure the brick would be installed in a perfectly straight line.

You should be attracted to clay because it’s an abundant natural resource. Brick technology dates back thousands of years. It’s a time-tested building material. Thousands of miles of roadways have been paved with hard-fired clay brick. Just weeks ago one of my newsletter subscribers sent me one of the thick historic dark-brown clay pavers used to build the famous Brick Road in Florida. That historic brick is now sitting on a shelf in my office. Visit Athens, Ohio, and go downtown. You’ll see hundreds of paving brick that are still in use today in their downtown district.

This is a real clay paving brick made by the Southern Clay Brick Company. It's 8 and 5/8ths inches long, 4 inches wide, and 3 inches thick. It was salvaged from the Old Brick Road in central Florida. Copyright 2023 Tim Carter

Instead of using the thick traditional clay pavers, I’m using a split paver that measures just under 4 inches wide by just under 8 inches long and is only a little over an inch thick. You can set it in a sand/cement base, but I’m going the extra mile and mortar each brick on top of a steel-reinforced concrete pad. Once complete, you could drive a truck onto my son’s patio and it would not crack.

The remarkable thing about this system is the ease of installation. You might think it’s not DIY friendly. In fact, it’s the opposite. The only really hard thing about the job in my opinion is getting the concrete slab poured correctly.

It’s vital the slab be in the same plane and flat. This means there can’t be any humps or deep furrows in the concrete. Any decent concrete mason can screed the concrete to achieve this goal. I poured my son’s concrete 5 inches thick and put the 1/2-inch steel rebars two feet on center in both directions. The steel looked like a piece of giant graph paper before it was entombed in the wet concrete.

Over the years I’ve discovered the best way to install these bricks is to install the border brick first. This is especially true if your patio or sidewalk is going to have curves. A square or rectangular patio is by far the easiest to build as it will require minimal cuts. We have a mix of straight and curved edges at my son’s house but I made sure that the overall size of the patio will have full-sized brick requiring no cuts. It just so happens that three rows of the brick we’re using equals 12 inches. His patio will end up having 45 rows.

The mortar mix is easy to make. I have my son mixing three parts of fine sand with one part of Portland cement. I have him mix just two or three gallons at a time in a wheelbarrow. Just enough water is added to make the mix resemble wet applesauce.

I lay each brick in enough mortar so it oozes up the sides about one-half inch. The rest of the joint is filled at the end of the job once all the brick are in place. I use a special big bag just like bakers use to decorate a cake. However, I don’t use icing! I blend one part very fine sand to one part Portland cement to make my grout.

Here I am using my 45-year-old Marshalltown trowel to install one of the thousands of split clay pavers that will create my son's patio. Copyright 2023 Tim Carter

The grout would probably test out in excess of 12,000 pounds per square inch. It wears like iron and will resist freezing weather for decades. I’m in the process of recording several in-depth videos of the installation process.

Column 1517