Composite Decking Mushroom | Mushrooms growing out of the bottom of Trex composite decking can’t possibly be a good thing. Decaying wood inside the Trex is fueling the mushroom growth. PHOTO CREDIT: Tim Carter

Composite Decking Mushrooms TIPS

- Some composite decking materials are made with wood fibers

- Many deck problems are caused by FAILURE of installer to follow instructions

- Read updated author's notes at bottom of column

- Ventilation is very important as is spacing between decking boards

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I had to replace a damaged Trex decking board on my ground-level deck and was shocked at what I discovered. On the underside of the decking, mushrooms and fungus were growing out of the decking!

I thought that composite decking materials were problem-free. I thought the reason to purchase these products was so that you’d never have to replace them.

What’s going on? What can I do to stop the growth of the mushrooms? Patti L., Woodinville, WA

DEAR PATTI: Oh my goodness! I’m not really surprised by this, especially since I’ve had firsthand experience with this myself.

How Did You Discover the Mushrooms?

Recently, I had to repair a poorly designed front porch that was covered with Trex decking. It was important to salvage the decking material, and as I carefully removed each board, I was stunned to discover large patches of white fungus and different species of mushrooms growing on the underside of the decking.

IMPORTANT NOTE: The mushroom growth problem was caused by the home builder, not a defect in the Trex decking. I didn't build the house I currently live in.

The builder didn't:

- provide any spacing between the decking boards

- it was too close to the ground

- it was enclosed on THREE SIDES

Because the deck was enclosed on the three sides, it was impossible to get air moving under the decking. You need air moving to evaporate any water that will fuel the growth of mold and mushrooms.

Get FREE and FAST BIDS from local deck contractors who know how to follow instructions.

Author's Note: Would you like to see three High-Resolution photos of the mushrooms that were growing out of the Trex Decking? If so, click here.

Is Decking Spacing Important?

The first thing I did once I got inside and cleaned up was to go to the latest written installation instructions published by the manufacturer. I immediately discovered that part of the problem in my case was the boards had not been spaced properly to provide some ventilation.

How Big Should the Space Between Boards Be?

The current written instructions show that there should be a 1/4-inch gap between the boards to provide for both expansion and air circulation. However, I was shocked to discover there was no real minimum clearance distance referenced with respect to how close the bottom of the decking should be to moist and dark soil. These are the conditions that mushrooms, mold and fungus seem to thrive in.

Was the Marketing Message Misleading?

Clever marketing has for years set up an unrealistic expectation, in my opinion, that composite decks are maintenance-free. I can remember years ago that this absolutely was the case with Trex. After it was in the marketplace for several years and problems started to happen, it became clear you had to maintain the decks.

Can you Re-Stain Faded Composite Decking?

I was shocked to discover in the installation and maintenance instructions the manufacturer even talks about how to stain the deck to restore the decking to its original color. That communicates to me they know the decking is going to fade and will need to be cared for if you want it to look good for years to come. So much for maintenance-free.

What Do the Mushrooms Eat?

The mushrooms are growing because they are feeding on the wood fibers inside the Trex decking. The literature from the manufacturer says the decking does absorb moisture.

I’m reasonably confident the wood fibers that are used in the decking are not treated to prevent wood rot or decay. I can’t find any information in the Trex literature that says they do treat the wood to prevent rot.

If this is the case, that the wood fibers are not treated, then it makes perfect sense why you, I and perhaps tens of thousands of others are experiencing hidden mushroom growth.

What Fuels the Mushroom Growth?

The wood fibers inside the decking are getting wet, rotting, and fueling the growth of mushrooms. That’s what happens to logs that fall in the forest and get wet. It makes sense rot could happen with composite decking that uses wood fibers or wood flour that’s not treated to prevent rot.

How Do You Prevent Mushrooms?

To prevent the growth of mushrooms, fungus and mold on the underside of your decking, you may want to consider implementing what I’m doing. The front porch I’m rebuilding is going to have new and vastly improved ventilation.

Not only will I be spacing the decking boards so that there is a minimum of 1/4 inch between the boards, I’m creating a minimum of a 1 and 1/2-inch gap around three sides of the decking where it used to connect directly to the house.

This air gap should be plenty to help keep the relative humidity on the underside of the decking to a point where the growth of the organisms will be stopped or significantly slowed.

Should I Regrade the Soil?

I’m also going to try to regrade the soil so there are at least 16 inches of air space between the soil and the underside of the decking. It helps that I have well-drained soil under the porch I’m working on.

If you have poor-draining soil, I suggest you take whatever measures are necessary to prevent the ponding of water under the decking.

Why is Airflow Under the Decking Important?

Airflow is perhaps the best way to ensure there’s no or minimal growth of mushrooms and fungus. The goal is to keep the moisture content of the wood fibers inside the Trex as dry as possible. Air movement absolutely accelerates drying.

Since the manufacturer admits the decking does absorb moisture, anyone with Trex decking needs it to dry as soon as possible when it gets wet. This does become problematic in areas that experience lots of rain over months of time.

In these locations, it’s probably best to avoid the use of composite decking materials that contain wood fibers that have not been treated with chemicals that prevent wood rot.

Author's UPDATE:

In the summer of 2016, I replaced all of the generation-one Trex decking at my home with Trex Transcend. The Transcend product has the same, or similar, core of wood fibers that are encapsulated by plastic.

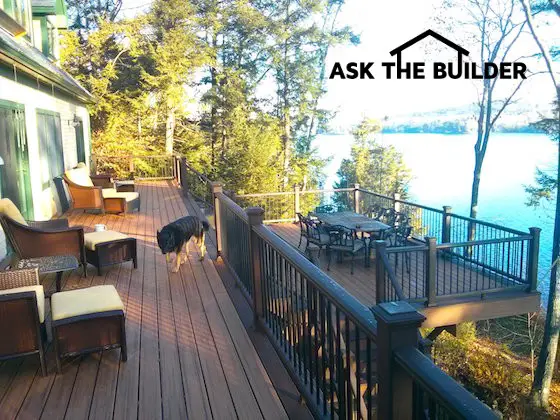

Here's my own Trex Transcend deck. There's lots of railing. It didn't take long to understand how to do it with professional results. Copyright 2021 Tim Carter

But the big difference is the top of each plank and the top third of each side is capped with a solid plastic that's embossed with wood grain. The capping material also has some extra coloration to simulate the real look of wood. My wife is a very tough critic of all things that are made to simulate wood. She feels this is the closest she's ever seen of any product to replicate real wood.

The small samples you get to hold in your hand look odd and unrealistic. But when the planks are down on the entire deck and you look out across it from a distance, it looks like real wood.

Here are some photos of my new Trex Transcend deck:

This is a photo of the decks under construction. The long deck with the furniture on them is the original 10 x 60-foot deck. The lower deck is new and is 24 feet wide and extends out 16 feet from the original deck. Copyright 2017 Tim Carter

The deck is complete with the Trex Transcend railing system. It was a pleasure working with this new material. It's engineered for easy installation and has all hidden fasteners for the decking and railing system. Lady the Dog loved laying on it. RIP Lady! Copyright 2017 Tim Carter

You can get a feel of the coloration in the medium-brown colored decking. The deck has a picture frame of darker material - Lava Rock - and the main decking is Tiki Torch. Copyright 2017 Tim Carter

Get FREE and FAST BIDS from local deck contractors who know how to follow instructions.

Column 903