Happy Friday!

I've got a boatload of new tips to share and great news about my Roofing Ripoff book below.

I also need your input on a very important four-question survey.

The weather forecasters say Spring is going to show up here in New Hampshire. Sunny days and warm temperatures are supposed to start happening next Monday.

Not a day too soon!!!

Let's get into some good stuff, enough about snow, ice and chilly weather!

Roofing Ripoff Book News

Two hours ago, I sent the final copy of my book to my high-priced libel attorney for his final review.

Today all of the components you need to get to PROTECT your existing asphalt shingle roof, or the new one you're about to install, should be at the fulfillment center.

I've not been able to release the book until I had ready for you WHAT YOU NEED to protect your investment.

This means early next week you should be able to get the book in electronic format. It will be available in paperback, but that's a few weeks out.

If the attorney gives me a thumbs up today, and it's possible, I will have a few FREE sample chapters for you on Sunday.

I thought this day would never come, but it's been worth the wait.

If you're a new subscriber and wonder what this is all about, go to the official Roofing Ripoff website. CLICK HERE.

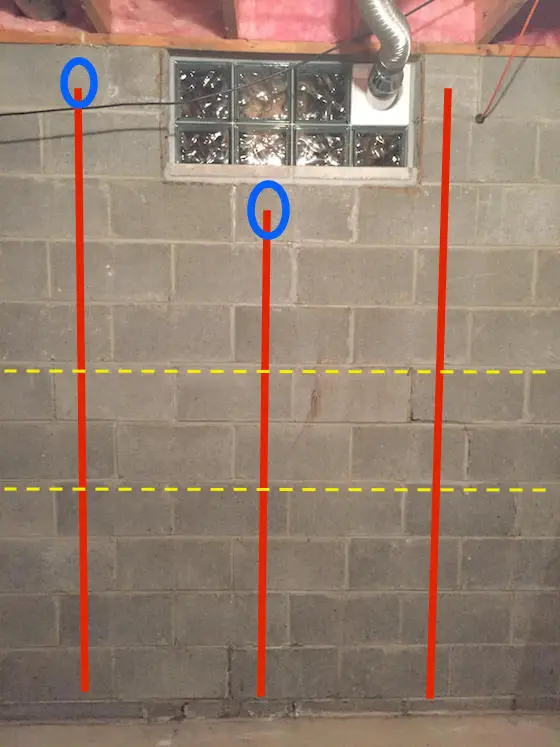

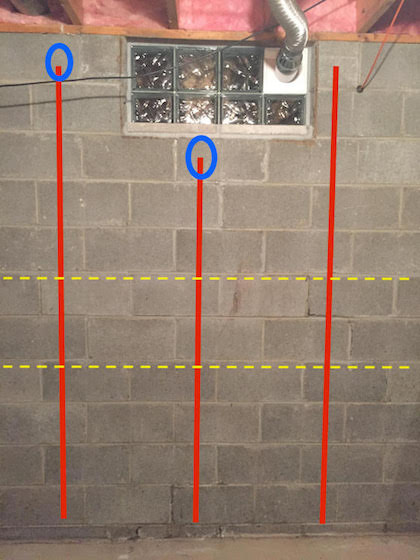

Cracked Concrete Block Foundation Repair

Do you know someone who has a concrete block foundation?

They often develop a horizontal crack about halfway up the wall.

Do you want to know what all the colored lines and ovals represent? I thought so!

CLICK HERE now and I'll bet you discover something new.

Guest Post Request

Yesterday afternoon I received an email from Ms. Sarah Walsh who works for a company I've never heard of - Web Talent Marketing. They say they're in Lancaster, PA.

I get an email like Sarah's about once or twice a month.

Sarah was probing to see if I accepted guest posts from companies.

A guest or sponsored post is one where the content is created by someone other than the owner of the website. In this case, Armstrong Flooring was going to create some column about flooring. They just wanted me to place it on my website HOPING that you'd see it.

Websites like AsktheBuilder.com often charge money to do this. Think of it as charging rent for space in a shopping mall.

MY POLICY at AsktheBuilder.com has always been that I DO NOT accept guest posts.

I entered into a back-and-forth discussion probing with Sarah as to what Armstrong was trying to accomplish.

Here was Sarah's reply about ninety minutes ago:

"I reach out to publications on behalf of Armstrong Flooring, but they create the guest content for publications like yours. As for a post buried deep in web search, our main goal of this relationship and post is to connect with your readers, not the entirety of the internet at once. Please let me know if you have additional questions!"

I responded back to Sarah telling her I felt that very few people have the time to just wander around to websites to see what's new.

What's more, I shared with Sarah that I felt folks like you discounted this content.

Let's see if I'm right. If not, I'll GLADLY admit my error.

Please take this SHORT four-question survey and let's see how you feel about surfing the web and this new trend of guest and sponsored posts at websites!

CLICK HERE to take the survey.

I'll SHARE THE RESULTS in a few days.

Window Seats

Have you ever wanted a window seat? They can be very comfortable and they add a very neat cool factor to most homes.

If you're building new, you should absolutely consider adding alcoves where you can put one or two in.

CLICK HERE to see a window seat I created here at my house in just TWO DAYS with a few simple tools.

The best part is I share HOW to create a window seat with virtually NO CARPENTRY SKILLS. You can buy the parts already preassembled!!!

DIY Wood Rot Treatment - Preventative Liquid!

How would you like to treat lumber to prevent wood rot?

You can't always get treated lumber like you want it.

Guess what? I share a magic liquid you can buy that will work really really well!!

CLUE: Cutty Sark and Thermopylae

CLICK HERE to see what it is.

Replacement Window Time?

Have you decided this is the year you're going to bite the bullet and get new windows?

If so, you REALLY can get taken by a salesperson.

Would you like to know what the BEST WINDOWS are? I thought so.

CLICK HERE to see what replacement windows I'd buy.

P.S. I give you links in the column so you can get FREE & FAST BIDS from local window companies that can get you the best windows!!

Maggie's Fireplace

Maggie is a long-time subscriber to this newsletter. I hope to meet her one day. She lives in North Carolina.

About two weeks ago, she reached out to me asking the best way to clean her interior fireplace.

She was sick of the way it looked and wanted to really brighten the room.

What do you think she was going to do?

Wait until you see the AMAZING PHOTOS she took of the before, during and after!!

CLICK HERE to see what Maggie did and then consider doing a project of your own.

I'd really appreciate it if you'd then SEND me your photos and comments!

That's enough for today.

Are you as excited as I am about the Roofing Ripoff book?

Tim Carter

Founder - www.AsktheBuilder.com

Do It Right, Not Over!