Roof Shingles with Copper TIPS

- Some shingles come with small amounts of copper in the granules

- Copper strips at the top are the BEST way to stop black algae stains - SEE BELOW

- Watch roof algae and moss video below

- Read the Roofing Ripoff book to get the full story

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

Asphalt shingles are a very common building material in many new homes built in the Midwest. Even homes that cost a cool seven figures can sport premium cut shingles that look like slate or cedar shakes.

Black Stains & Streaks

But no matter how much you spend on your new home or its roof, the shingles can develop ugly black streaks in short order if you don't purchase special algae-resistant shingles. That said, there's a better way to prevent the black stains. I cover it below, so keep reading.

The ugly stains I am talking about often look like upside down ice cream cones. Far up on north or east facing roofs, you may see a small black spot and a widening fan of black that grows and spreads as it heads towards the gutter line. There can be multiple areas of this streaking.

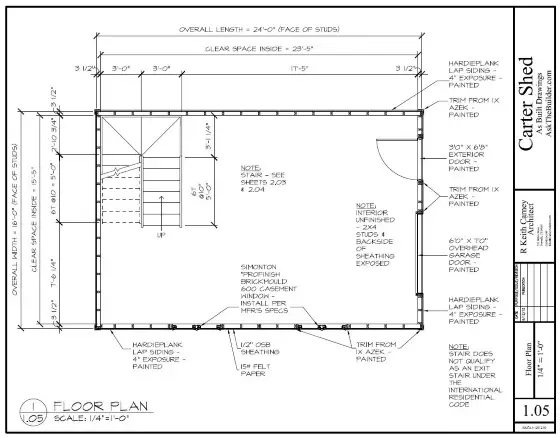

In the photo below, the algae stains have consumed the entire roof except for two areas. You don't see the ice-cream cone look here.

Much of this roof is covered with black algae streaks. But two areas are not because of the metal that washes onto the roof each time it rains. At the top of the roof is a cupola with a copper roof. Copper is the key to stopping algae stains. Copyright 2017 Tim Carter ALL RIGHTS RESERVED

In the worst cases, the entire roof turns a disgraceful color of deep gray or black.

Microscopic Algae

The cause of this streaking is a simple organism - Gloeocapsa magma. This microscopic organism or algae actually eats an ingredient found in many asphalt shingles.

The algae is harmless and the feeding does not cause any damage whatsoever to the shingles. The dark coloration is simply a buildup of the dead dark discolored cells that sluff off of the actively growing algae.

The algae organism has been around for years but it only recently became a problem because of a significant change in how asphalt shingles are made. Years ago a heavy felt paper was used as the foundation of the shingle.

This thick felt mat absorbed the liquid asphalt that creates the waterproof barrier on your roof. The felt was made from cheap cotton rags. But the introduction of polyester fabrics decades years ago caused the cotton rag market to shrink. Due to a dwindling supply of raw materials, the felt manufactures developed fiberglass mats and thus fiberglass shingles were born.

Too Much Limestone?

But the trouble with fiberglass is that it didn't absorb as much asphalt and the resulting shingle was simply too lightweight. Shingle manufacturers decided to add weight to the shingles by combining powdered limestone with the liquid asphalt.

It worked. The resulting shingles were close to the original weight of those made with the traditional thick felt mats.

No Black Decades Ago

But the evidence suggests that some shingle manufacturers might be adding too much limestone to their shingles. Black algae stains were not normal decades ago. Limestone is cheaper than asphalt.

If you were a publicly traded shingle manufacturer and Wall Street analysts were on quarterly conference calls probing how you were going to increase profits, what might you do?

Would you start to lower the cost of making your shingles? Would you take shortcuts?

Heat & Humidity

Everyone seemed to be happy for a few years but all of a sudden roofs in humid climates started to develop the black streaking. Upon investigation, it turns out that the powdered limestone was a scrumptious food for the algae!

The algae had been on roofs for years, but it never was able to grow as there was not enough to eat. It's my opinion that decades ago there was a lower amount of limestone in the shingles and the asphalt coated it so well the algae couldn't get to the food.

If there's a higher amount of limestone in the mix as a filler, then there's a greater chance some of the limestone will be at the surface of the shingles and/or have a lighter coating of asphalt that wears away exposing the limestone to the algae.

Copper = Natural Biocide

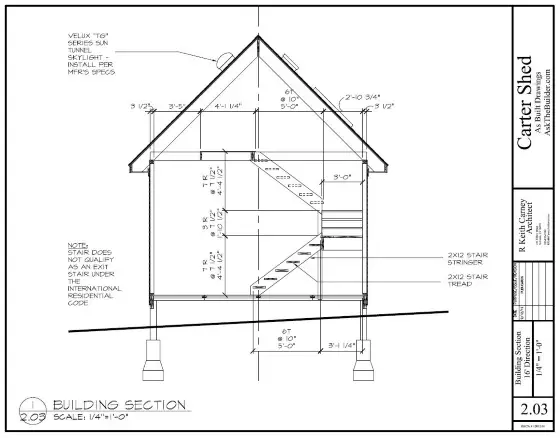

It didn't take too long to figure out how to prevent the growth of algae on roofs. Those roofs that sported copper or zinc metal flashings at plumbing vent pipes, chimneys or ridges had no algae growth below those areas where the flashing was exposed to the weather.

If you want to STOP algae staining just install copper strips on your roof. On most roofs you can't see these from the ground. The copper weathers FAST to a gorgeous nut brown in a few months. Click on the image to purchase copper strips for your roof.

These metal flashings sacrifice small amounts of the actual metal due to the ultraviolet light of the sun. About five percent of the UV rays contain energetic photons that blast apart the copper atomic bonds. Each time it rained, some of the copper or zinc washed down on to the roofs. This microscopic bits of metal poisoned the algae and it simply would not grow.

Roof Algae & Moss Removal Video

Watch this video for proof positive about how well copper works to keep algae and moss from a roof. It's my own home!!!

Best Protection

The good news is that you can buy new shingles that have copper built in to the colored granules. You can't see the copper, but it is there. It weathers just the same as a solid metal flashing and the entire roof surface becomes unpalatable to the algae.

The issue is I bought some of these shingles to put on my own garden shed and it still developed the black algae. It's my belief the manufacturer didn't put enough of the copper-coated granules in the shingles.

The best way to STOP the black stains is to install solid copper strips up at the ridge line of your roof or along the angled hips if you have a hip roof.

If you do this, you'll also extend the life of your asphalt shingles by decades.

I wrote a book about why asphalt shingles are falling apart and discovered in the process how copper can slow the oxidation of asphalt. You can get all the details in my Roofing Ripoff book.

Source of BEST Copper

I tried to get a patent on my discovery but it's not possible. So I decided to come up with a way for you to get the best copper for the LEAST amount of money.

You can buy the copper you need to prevent the black stains from me or anyone else you choose.

I sell the perfect weight of copper and mine comes with the correct nails you need to install it.

Go to www.copperroofstrips.com to get it.

Clean With Oxygen Bleach

If your existing roof is stained with the algae and you need to clean it so you sell your house for more money, you can clean the roof. I have found that oxygen bleach is the safest way to do this job. Oxygen bleach is a powder that is mixed with water.

Watch the video just below to see how to remove algae stains from roofs using Stain Solver oxygen bleach.

You apply the solution to a cool roof and let it soak for 20 to 30 minutes. It is important to keep the roof surface wet with the solution. At the end of the wait period, lightly scrub with a push broom and rinse with a garden hose.

Difficult stains may require multiple cleanings.

Once the existing roof is clean, you can keep it algae-free by installing strips of copper at key locations. You simply want rain water to be able to hit a 6-inch wide area of copper.

Install the strips at the top roof ridge and any other place at the top of a roof so that you are fully protected. PURCHASE the copper strips you need using this link.

For more, read Tim's Beware Miracle Transformation Products.

Bulletin 082