Preventing Squeaky Floor TIPS

- Know causes first so you can nip squeaks in the bud

- Nail shaft movement most common cause

- WATCH floor squeak solution video below

- Use great subfloor adhesives - see below - and screw the floor

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

How many old homes have you walked through where you hear annoying squeaks with each footstep? If you live in such a home it is possible, in certain instances, to get used to the noise.

Somehow your brain seems to block it out. It is even possible to sometimes cure squeaky floors. But most people I know who are buying or building a new home will not and should not tolerate squeaky floors.

After all, preventing squeaks in wood floors is as simple as falling off a log. Anyone can do that.

Common Squeak Causes

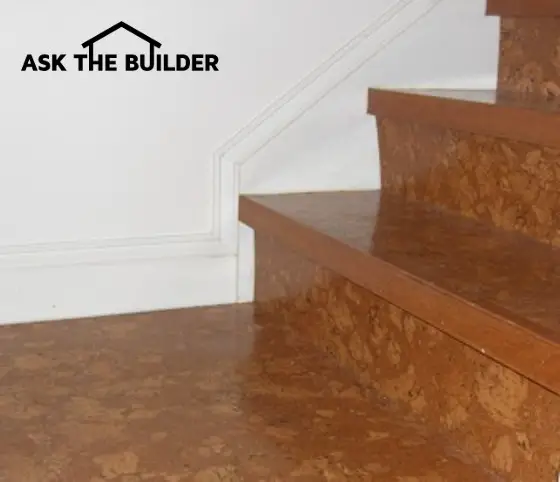

Squeaks in wood floors can be traced to any number of causes. Perhaps the most common cause is wood sub-flooring that is not tightly secured to the floor joists.

In many instances, the loose sub-flooring sits slightly above the floor joist. When a person walks across the sub-flooring, their weight causes the wood flooring to move down until it contacts the floor joist.

As the person walks away from that spot, the wood flooring rises up to its original position.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors that can solve your squeaks.

Nail Shafts Are Source

As the wood sub-flooring is going up and down, it slides past the nail shafts of the nails that were used by the carpenter to fasten the sub-flooring to the joists. The movement of the wood along the nail shafts produces the annoying squeak.

Floor Squeak Solution Video

Watch the following video to see one way to stop floor squeaks.

Metal Ductwork

Squeaks can also originate from metal ductwork that delivers heated and air conditioned air into each room of your new home. The installer of the metal ductwork, if not careful, can install this sheet metal ducting such that it gets into a slight bind.

As you walk across the floor, downward pressure on the ductwork can create the oilcan effect and cause the metal ducting to squeak or pop.

Old Diagonal Bridging

Some carpenters and builders may also use diagonal bridging in between floor joists. The individual pieces of bridging that create the letter X in between the joists must not touch one another.

There should be a spacing of approximately one-half inch so that they can move independently as loads are placed upon the floor joists. If the bracing touches and moves, it can also produce the elusive squeak that causes the grimace on your face.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors that can solve your squeaks.

Prevention

As you might imagine, knowing the causes, allows you to be proactive in preventing floor squeaks in your new home. I encourage frank discussions with the builder or the sub-division sales agent during the planning stages.

Ask pointed questions as to how squeaks will be prevented. Beware of answers that include glue and ring shanked nails. I've walked across hundreds of floors that have been glued and fastened with ring shanked nails that squeak horribly.

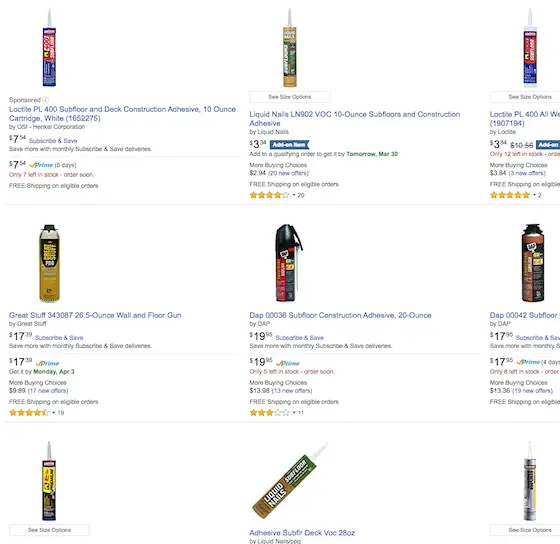

Subfloor Adhesives

The chemistry of subfloor adhesives has come a long way. Each manufacturer is trying to outdo the other.

Those that make great products stand to capture large chunks of the marketplace. Here are a few of the adhesives that are quite popular:

There are quite a few subfloor adhesives. Here's one way to locate the best one. The BEST ONES usually contain MORE of the GREAT INGREDIENTS so they cost more. Use price as your barometer. CLICK THE IMAGE TO ORDER SOME ADHESIVE NOW AND IT WILL BE DELIVERED TO YOU.

Granted, if used properly, sub-floor adhesive and ring shanked nails can minimize or eliminate many squeaks. But all too often, the glue and the nails are not installed correctly. Catching work defects is another great way to stop squeaks before they get covered up.

Glue Skins Over

One of the reasons subfloor adhesive fails is the glue can skin over before the wood subfloor is attached to the floor joists. Some rough carpenters put down a sheet of subfloor and only tack the corners or edges.

If the panel has any bow up or down to it, there's a void space between the panel and the joist. The glue can then skin over and when the panel is eventually nailed, the glue serves no purpose.

Nail Immediately

The subfloor panel needs to be nailed or screwed to the joist completely as soon as it's put down. The spacing of the fasteners might be one every 8 inches along each joist.

Do Inspections

Be sure to visit your new home as it is built. It is vitally important that you ask for permission and be aware of safety hazards when you do construction site visits. Inspect it as often as possible for defects that cause squeaks.

Try to visit the job site early in the morning when it is quiet. Walk through the home and listen for squeaks. It may take repeated visits to discover squeaks because of wet or damp framing lumber.

Wet Lumber Masks Squeaks

Wet lumber can swell and this often masks squeaks. As the lumber dries and shrinks, the conditions for squeak production increase. You absolutely must do an intense survey just before drywall is applied to walls and ceilings.

Screw Hallways & Main Room Pathways

Wood sub-flooring can be screwed to floor joists before finished flooring is installed. Use coarse threaded drywall screws that penetrate at least three quarter inch into the floor joists. Be sure the flooring in all hallways and in the open areas of rooms is screwed to the joists.

Once finished floors are installed, it can be an enormous challenge to fix squeaky floors. Prevention of squeaks is absolutely the best course of action.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors that can solve your squeaks.

Related Column = Floor Squeak and Bounce Repair

Column NH048