Backfilling a Foundation Wall - Believe it or not, this is a precast foundation wall. It is made from poured concrete and rests on compacted gravel, not a poured concrete footer. If this wall was backfilled before the interior floor was poured, it would collapse in no time. ©2023 Tim Carter

Backfilling Foundation Wall TIPS

- Concrete takes weeks to get strong

- Cold weather slows strength building

- Vertical steel bars are best to prevent failure

- Steel placement location critical

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I am building a new home and the poured concrete foundation was installed 17 days ago. The weather has been cool with temperatures averaging about 51 F.

I was told to let the concrete cure for 25-30 days before backfilling it. However, the contractor is applying pressure to backfill so the rough carpentry subs can get to work.

Should I cave in and let them backfill against the walls or should I suffer the consequences of delaying the project? Shawn S., Pittsburgh, PA

DEAR SHAWN: In my opinion, concrete is a mystical building material. That said, you want to know about backfilling a foundation.

When Should A Foundation Be Backfilled?

A poured concrete foundation should be backfilled AFTER:

- the concrete has achieved a minimum of 75% of its design strength

- the basement slab, if there is one, has been installed. It acts as a support column at the base of the wall preventing it from sliding off the footing

- the wood subfloor has been installed. The floor joists and subfloor assembly once bolted to the top of the foundation act as a support column at the top of the poured wall.

Think of a poured concrete wall as a BIG BEAM that needs support at each end (top and bottom) just like a floor joist needs support at each end. The soil is applying sideways pressure to the foundation wall just as a heavy load applies downward pressure to a floor joist.

Concrete is Liquid Rock

It often arrives at a job site in a truck pre-mixed and ready to pour. Typically it has the consistency of cooked oatmeal, but hours later it resembles damp solid rock.

CLICK HERE to get FREE & FAST BIDS from local foundation contractors near you!

This transformation happens because of a chemical reaction that starts to happen the instant water is added to the Portland cement powder. The hydration chemical reaction causes microscopic crystals to grow that connect all of the sand and gravel to one another.

Concrete Strength Achieved After Many Weeks

The trouble is, this chemical reaction continues for weeks, and even months, after the concrete truck leaves the job site. In fact, standard concrete that is moist cured under ideal conditions often only achieves 40-45 percent of its design strength after three days.

After seven days, it should hit 75 percent of its final design strength. To get to 100% of it's design strength, you often have to wait 28 days or more. These numbers assume temperatures at or near 70F.

Cold Temperature Slows Strength

In cold weather, the strength-building process can slow considerably and even stop completely if the temperature gets very cold. Once the weather warms up, the concrete starts to strengthen again on its own so long as it still retains moisture.

That's why it's a big risk to backfill a cast, or poured, concrete foundation during the winter. You can build on top of the foundation with little risk.

It's the weight of all the dirt pressing against the new, tender concrete that's the issue.

This is what happens when you backfill a foundation too early. The red line indicates WHERE the top of the wall should be - in a straight line. Look at the snow on the ground. The builder of this home is an IDIOT. Copyright 2023 Tim Carter ALL RIGHTS RESERVED

When Should A Foundation Be Backfilled?

A poured concrete foundation should not be backfilled until:

- the concrete has achieved a minimum of 75% of its design strength

- the basement slab, if there is one, must be installed. It acts as a support column at the base of the wall preventing it from sliding off the footing

- the wood subfloor must be installed. It acts as a support column at the top of the poured wall.

Think of a poured concrete wall as a BIG BEAM that needs support at each end (top and bottom) just like a floor joist needs support at each end. The soil is applying sideways pressure to the foundation wall just as a heavy load applies downward pressure to a floor joist.

Vertical Steel Prevents Horizontal Bending

If you had told me that you had vertical steel reinforcing bars in the poured concrete, then maybe I would say to move ahead and backfill. But vertical reinforcing steel is rarely placed in residential concrete foundation walls.

It's not hard to put it in, but it does cost extra money.

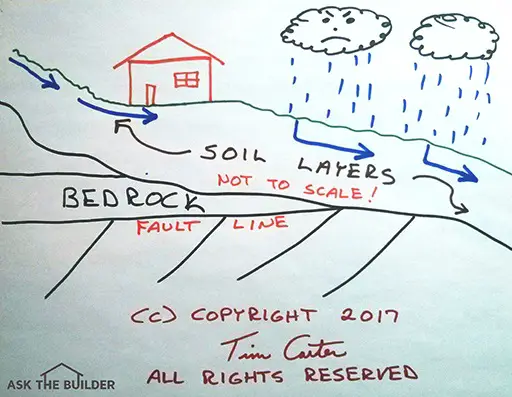

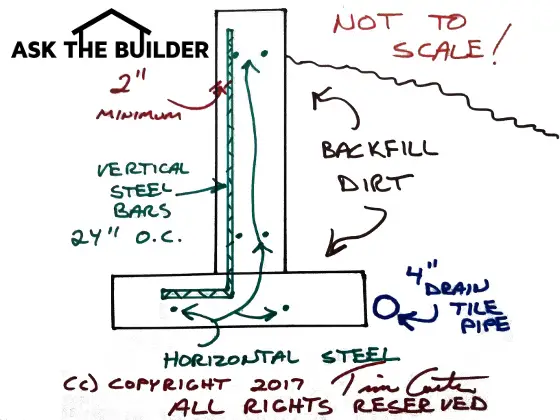

If you decide to put vertical steel in a foundation wall to resist backfill pressure, the steel needs to be placed closer to the inside face of the wall. The usual standard is 2 inches.

This ATB drawing done in haste shows vertical and horizontal steel bars using teal color. There are four horizontal bars in the foundation wall and two in the footing. You can see the vertical steel bar. These would be put every 2 feet on center. NOTE: The vertical steel bars start at 2 inches from the inner face of the foundation wall. This placement is CRITICAL. ©2017 Tim Carter

Horizontal Steel Common

Foundation walls often have two rows of horizontal reinforcing steel placed near the bottom and top of the walls. This steel helps prevent vertical cracks in the foundation walls should the soil beneath the foundation shift or move. This movement is an up and down movement.

This steel is usually about one foot up from the top of the footing and one foot down from the top of the wall.

CLICK HERE to get FREE & FAST BIDS from local foundation contractors near you!

Backfill Creates Sideways Pressure

Backfill dirt that is placed against the foundation wall causes a lateral or sideways movement. Vertical steel bars add enormous strength to poured concrete and help prevent horizontal cracks that are caused by soil pressures.

Loaders & Dozers Are BAD!

Lateral pressure can also be caused by the heavy machinery that places the dirt against the walls. An inexperienced heavy equipment operator can crack a new foundation wall by pushing dirt into the void space against the wall instead of gently dropping it in from above.

Walls = Wide Beams

Backfilling a poured concrete wall or even a masonry concrete block wall can be very risky if two other tradespeople are not finished with their work. The basement slab and the first floor that sits on top of the foundation should be complete before backfilling proceeds.

These two building systems help lock the bottom and top of the foundation walls in place as the soil pressure pushes against the walls. I've seen poured concrete foundations that were backfilled before a basement slab was poured. In certain instances the wall cracked and slid off the footer from the intense soil pressure.

Backfill Dirt Is Heavy

Keep in mind that wet soil is very heavy. It's not uncommon for this material to weigh nearly 100 pounds per cubic foot. When you calculate the weight of all of the soil being dumped against the foundation you quickly discover it is tens of thousands of pounds.

A foundation wall is just a concrete slab turned on edge. Concentrated loads routinely crack flat concrete slabs so it's not hard to imagine soil pressure creating a crack.

Patience Pays Off

My advice to you is to wait. Your builder and many others will scoff at you and will put pressure on you to move ahead. But this pressure pales in comparison to the weight of the dirt that is placed against the foundation walls.

Furthermore, if the foundation does crack because of premature backfilling, this structural scar will haunt you until you eventually sell your home. In fact, you will probably have to explain what happened to the professional home inspector that is hired by the buyers after they see the ugly cracked foundation walls.

Vertical Steel is Easy

The vertical steel bars that should be placed in poured concrete walls are not hard to install. It often only takes an experienced crew maybe one extra day, perhaps two, to install this valuable structural component.

Steel is 100X Stronger Than Concrete

The reason steel is needed is simple. Concrete has fantastic compressive strength. This means if you squeeze or compress it, it takes enormous pressure to crack concrete. But if you try to bend or pull concrete, it only has one-tenth the strength it exhibits when you compress it.

This bending of concrete is referred to as tension by engineers and concrete professionals. The mix used by many foundation contractors might only have 350 pounds per square inch of tensile strength.

Steel, on the other hand has enormous tensile strength. The steel bars a contractor would often buy would require 40,000 pounds of tension applied to them before they'd rip apart. That's over 100 times stronger than the concrete.

These steel bars, once placed inside the wet concrete, transfer their strength to the concrete. Imagine how strong a foundation wall might be that has vertical steel bars placed two-feet on center. I can tell you that a wall built this way will stand the test of time.

Column 569