Tar Paper Facts and Tips

Tar paper has a proven track record of success. It will keep this shed dry for hundreds of years if the shed is maintained. (C) Copyright 2017 Tim Carter

CLICK HERE or THE IMAGE NOW TO BUY TAR PAPER

Tar Paper TIPS

- Proven track record of performance

- Horizontal rows must overlap

- Easy to install

- Synthetic material options

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I'm building a room addition, and as I demolished my outside wall, I discovered tar paper was in the wall. I thought tar paper was just used on roofs.

Why did they use tar paper in the wall? Should I use it on the walls of my room addition? What about all the new fancy products I see that were developed to replace tar paper? It's all very confusing. Rob R., Lebanon, OH

DEAR ROB: I'd wager that hundreds of thousands of houses here in the USA, and possibly millions across the world, are still standing because smart builders of old used tar paper as a weather barrier.

You're correct that it's been used under roofing for years to help keep wood dry. It does the same thing on walls if given the chance.

Demolition Proves Tap Paper Works Well

I've also had the pleasure of tearing apart many an old exterior wall. On just about every one that was wood-framed, I found tar paper under the exterior siding material.

The tar paper had become brittle in almost all situations, but it still worked. You could put water on the black paper, the water beaded up and didn't penetrate to the wood behind.

Old-Growth Lumber

I don't know what builders of old used before tar paper, but I can only assume that once crude oil was discovered and then refined for it's many current uses, builders immediately saw the benefits of a waterproof product made from oil that could be applied in sheets.

One reason homes built before the 1900's didn't rot at the alarming rate you see lumber rot today is the old homes use old-growth timber.

This timber has a much more equal ratio of hard, dense summer wood to the less-dense spring wood. Summer wood is the dark band you see at the end of a cut log. Springwood is the light-colored band.

The spring wood is added to the tree in the spring when water is usually abundant. Come July, the wood that's added is much denser because it's usually dry that time of year. The summer wood, by it's very nature, is very rot resistant.

How Tar Paper is Made

Tar paper used to be made by soaking a porous paper made from cotton rag scraps with thinned liquid asphalt. Asphalt, of course, is one of the final products that comes out of a catalytic convertor that's used to refine crude oil.

The paper comes in different weights. The most common weights are 15-pound and 30-pound tar paper. The 30-pound tar paper is heavier and has much more asphalt in it.

Not the Same

While impossible to know unless you do an expensive analysis, the asphalt used to make modern tar paper contains much more oxygen than it should.

The tar paper made between 1900 and 1980 probably will last far longer than the tar paper made today.

Fiberglass Mats

Much of today's tar paper is made using multiple fiberglass mats as the cotton rag industry has declined significantly over the past few decades. This is just part of the reason why fiberglass shingles were introduced. There simply was a shortage of cotton scrap to make the mats that are the foundation of shingles.

The big reason fiberglass pushed aside cotton-fiber mats was they could run the giant mills three times faster than if they used cotton. This means more profits for the asphalt shingle manufacturers.

UV Damage

Since felt paper gets covered with something not long after it's installed, there's little chance it will degrade. The ultraviolet rays from the sun attack the exposed asphalt and cause it to oxidize and cross link with adjacent asphalt molecules. This cross linking makes the asphalt brittle.

Tar Paper is Time Tested

Using tar paper to protect wood sheathing and wood framing members on houses, room additions or outdoor sheds is a fantastic idea. This time-tested product is affordable, it's easy to work with and it's readily available.

Tar Paper Video

Watch this video to show you tar paper being installed on a large shed I built in the summer of 2013.

Overlap Correctly

The trick is to make sure you install it so it overlaps correctly. You want each piece to overlap the piece below it. Feathers on birds, fur on animals and shingles on a roof use this same method to stop water penetration.

It's all about shedding water. There are pre-printed lines on the tar paper that help show you where to end the overlap. Usually 2 inches is plenty on a horizontal seam. If you have a vertical seam where one piece ends and another starts, make the overlap at least 6 inches.

Overlap the Top of Your Foundation

Another great installation tip is to make sure the first strip of tar paper is installed so it overlaps the top of the foundation at least an inch. You want any water that does get behind the siding to run down and never be allowed to get near any wood. Many homeowners and builders fail to create this mission-critical overlap at the foundation.

New Weather Barriers

The newer weather barriers made from synthetic fabrics are great products. I've used them as well as tar paper. Some of the new products come in tall 10-foot-wide rolls that allow you to cover a typical one-story house with only one vertical overlap seam!

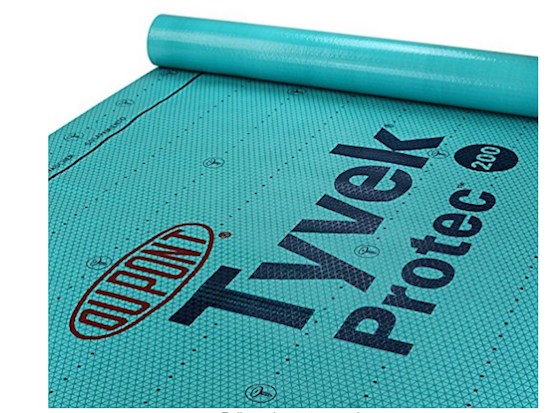

Here's a typical synthetic water barrier that takes the place of tar paper. This material is 4-feet wide and 250-feet long! CLICK THE IMAGE NOW TO BUY IT.

It's not uncommon to have a roll that's over 100 feet long, if not longer.

You surely can't do that with tar paper as it usually only comes in rolls 3-feet wide. This means you'll have at least four horizontal overlap seams in a typical single-story home.

More Labor

Tar paper will take more labor to install than the newer wider synthetic weather barriers, but if you're doing the work, it costs you just your time. You just need to do the math to see what material will save you money.

Drainage Channels

Some of the newer weather barriers have great drainage channels built into them. These channels help direct water quickly down and away from the exterior siding material. They also promote quick drying allowing air to get behind any siding. This is a good thing.

Tar paper does not offer this. Siding applied directly over tar paper creates a sandwich effect and can trap water between the siding material and the tar paper.

If you want vertical drainage with tar paper, you have to add treated lumber strips on top of the tar paper. This is a time-intensive process and requires all sorts of skill.

I don't add vertical drainage strips on my jobs when using tar paper because I take the time to install the siding so that water will have a very tough time getting to the tar paper. Just use the best practices when installing siding and you'll get the same results.

February 2, 2017 AsktheBuilder Newsletter

Column 950

20 Responses to Tar Paper Facts and Tips